Emergence of 3D to 4D Printing

Future Manufacturing via Smart Materials

BY Eng (Dr) Madhubhashitha Herath

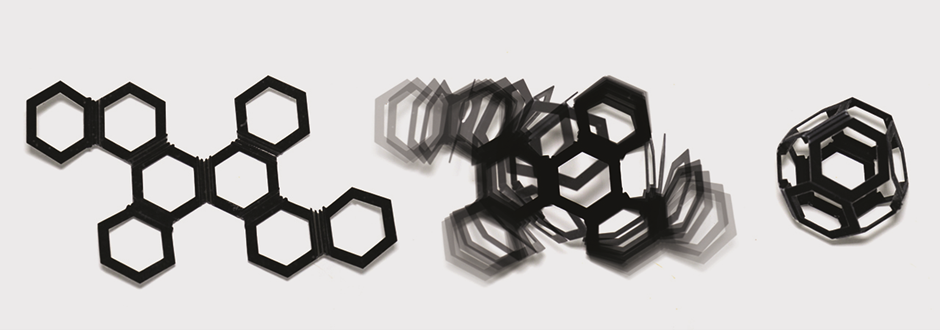

Source: https://eidonlab.org/additive-manufacturing-il-4d-printing/

Three-dimensional printing technology commonly known as 3D printing has substantially progressed in the past three and half decades. The additive manufacturing methods such as 3D printing enable engineers and scientists to fabricate complex geometries that are challenging with subtractive manufacturing methods such as machining. Automobile and aerospace manufacturers have taken the lead in 3D printing-based prototyping and production. In biomedical engineering, additive manufacturing is being used for customized implants. 3D organ bioprinting is an evolving scientific area that generates enormous commercial benefits.

4D printing has one more “D” than 3D printing and the fourth dimension that advances the 3D printing is time. Accordingly, 4D printing is referred to as 3D printing of objects that transform over time. Skylar Tibbits, the founder of the Self-assembly Lab at Massachusetts Institute of Technology (MIT) in the United States introduced to make use of smart materials for 3D printing to produce programmable objects. In 2013, during his talk at a TED conference, he suggested the name “4D printing” for this innovative technology. Today, 4D printing is extensively explored all around the globe.

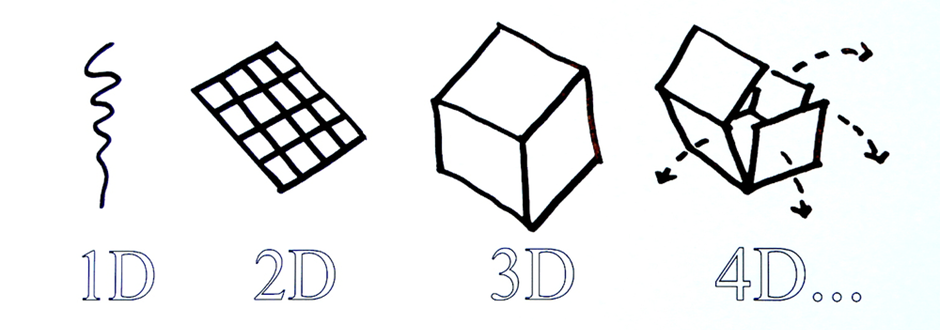

The breakthrough in 4D printing over 3D printing technology is its ability to change shape over time. That means a 3D printed object transforms itself into another geometry over the influence of external energy input such as heat, magnetic field, electricity, light, and microwave. With a single multi-material print, a product or mechanism can transform from any 1D strand into 3D shape, 2D surface into 3D shape or morph from one 3D shape into another.

Source: https://www.sculpteo.com/en/3d-learning-hub/best-articles-about-3d-printing/4d-printing-technology/

Research and developments in advanced printers, deformation mechanisms, and mathematical modelling have enhanced the prospects of 4D printing. Above all the recent advances in smart materials play a significant role in 4D printing. Materials such as nickel-titanium alloy and functionalized ceramics facilitate 4D printing. Compared to smart metals and ceramics, smart polymers have the advantages of diverse stimulus responsivities and large deformability. Therefore, 4D printing is more focused on utilizing polymer-based smart materials such as shape memory polymers, hydrogels, and liquid crystal elastomers.

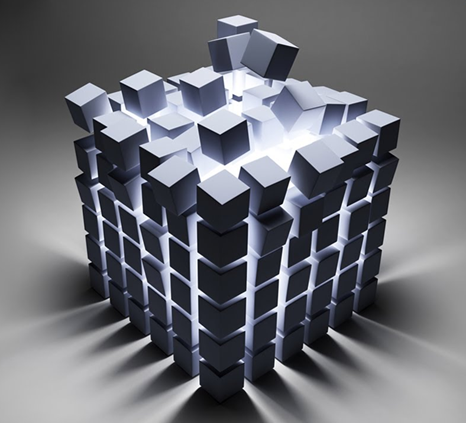

Source: https://new.abb.com/news/detail/62311/4d-printing

Imminent applications of 4D printing include deployable spacecraft components such as hinges, trusses, booms, antennas, optical reflectors, and morphing skins. Furthermore, soft robotic actuators can be fabricated without the reliance on complex and heavy electromechanical devices. At present 4D printing facilitate adaptive wearables and garments that respond to user demands and fluctuating environments. Ongoing research on self-repairing and self-assembly also take the advantage of 4D printing technology. Distinctly the medical sciences will boost to its next level owing to 4D printing. This technology will make a significant impact on biomedical applications such as targeted drug delivery, stents, and splints.

In the future non-living engineered complex-shaped objects could behave like living organisms by responding to external stimuli. 4D printing technology will enable autonomous products to evolve without the need for electromechanical components and computation capability in the device. As the fourth industrial revolution is well underway the combination of additive manufacturing, smart materials, and machine-learning will take product manufacturing to a new height.

Eng (Dr) Madhubhashitha Herath

Eng (Dr) Madhubhashitha Herath

PhD, MEng, BSc Eng, CEng, MIMechE (UK), MIE(SL)

Senior Lecturer, Department of Engineering Technology

Faculty of Technological Studies, Uva Wellassa University